RESOURCES

Chetak has the expertise to optimize your supply chain with tools that can help strengthen supplier relationships, reduce costs, balance inventory, improve customer service, and mitigate risk, thus delivering sustainable competitive advantage wherever you operate worldwide. We provide services that extend beyond the standard receiving, storing and shipping of products.

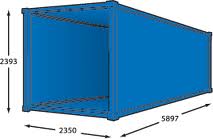

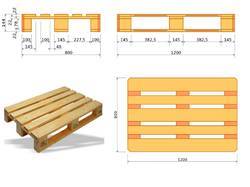

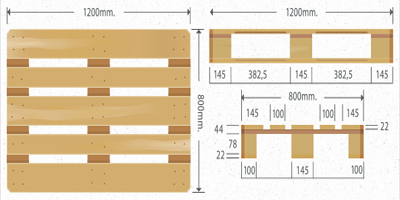

Dimensions

Varius dimensions are placed to provide you information for which helps you in taking right decesions.

|

||||||||

| Technical Specification | ||||||||

|

|

||||||||

| Technical Specification | ||||||||

|

|

||||||||

| Technical Specification | ||||||||

|

| 20 feet Single Axel (6 Tyre) | ||||||||||||||

|

||||||||||||||

| Technical Specification | Before increased Axel load | After increased Axel load | ||||||||||||

|

||||||||||||||

| 32 feet Single Axel (6 Tyre) | ||||||||||||

|

||||||||||||

|

| 19 feet (6 Tyre) | ||||||||

|

||||||||

| Technical Specification | ||||||||

|

| Double Axel | Torus (10 Tyre) | ||||||||||||||

|

||||||||||||||

| Technical Specification | Before increased Axel load | After increased Axel load | ||||||||||||

|

||||||||||||||

| 32 feet Single Axel (10 Tyre) | ||||||||||||

|

||||||||||||

|

| MXL (12 Tyre) | ||||||||||||||

|

||||||||||||||

| Technical Specification | Before increased Axel load | After increased Axel load | ||||||||||||

|

||||||||||||||

| 32 feet MXL (12 Tyre) | ||||||||||||||

|

||||||||||||||

| Technical Specification | Before increased Axel load | After increased Axel load | ||||||||||||

|

||||||||||||||

|

||||||||

| Technical Specification | ||||||||

|

|

||||||||

| Technical Specification | ||||||||

|

|

||||||||

| Technical Specification | ||||||||

|

|

||||||||

| Technical Specification | ||||||||

|

|

||||||||

| Technical Specification | ||||||||

|

|

||||||||

| Technical Specification | ||||||||

|

|

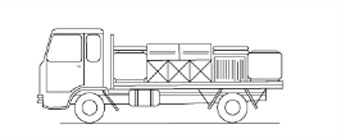

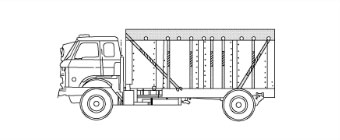

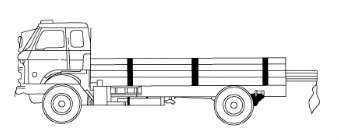

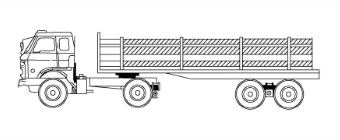

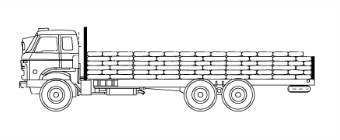

Namakkal/Anna body terminology is derived in South India. Namakkal is a district in Tamil Nadu. Most of the Truck owners and Drivers are from here in south India. Whereas Anna body word is derived word Anna which means Big Brother in Tamil language. When these vehicles come to North Indian they all the driver Anna and vehicles driven by them are called Anna Body vehicles. These vehicle technical specifications are available in all vehicle category. The only difference is in load body. Height of Namakkal load body is 2.5 feet from floor, which you can be seen in above picture. |

|

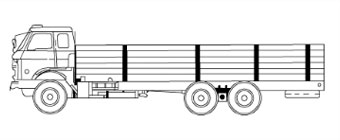

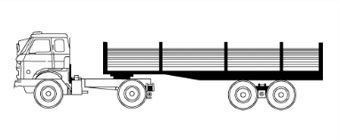

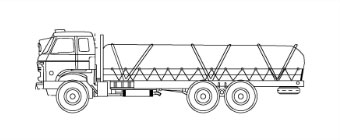

Punjab body terminology is derived from North India. Punjab is a State in north India. Most of the Truck owners and drivers are from Punjab state and mainly Sikh community dominated this business in long haul. Whereas Punjab body word is used by South Indian because of their identity. These words are used to remove language barriers and to identify vehicle type. These vehicle technical specifications are available in all vehicle category. The only difference is in load body. Height of Punjab load body is 7 feet from floor, which can be seen in above picture. |

|

||||||||||

| Technical Specification | ||||||||||

|

|

||||||||||

| Technical Specification | ||||||||||

|

|

||||||||||

| Technical Specification | ||||||||||

|

|

||||||||||

| Technical Specification | ||||||||||

|

|

||||||||||

| Technical Specification | ||||||||||

|

|

||||||||||

| Technical Specification | ||||||||||

|

|

||||||||||

| Technical Specification | ||||||||||

|

|

||||||||||

| Technical Specification | ||||||||||

|

|

||

| Physical Specification | ||

|

|

||

| Physical Specification | ||

|

|

||

| Physical Specification | ||

|

|

||

| Physical Specification | ||

|

Acceptable

Acceptable

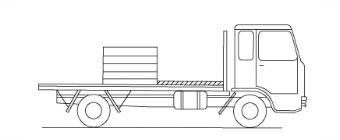

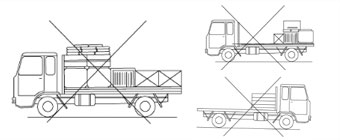

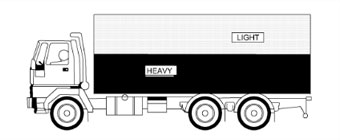

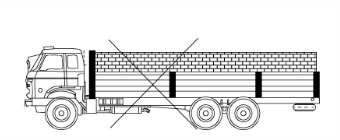

Badly distributed loads, such as heavy loads placed at the rear, at one side or at the front of the vehicle platform may cause the maximum axle weight, which may result for axle failure and extremely dangerous during travel for the crew of the vehicle and for other road users.

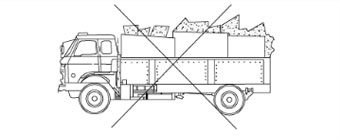

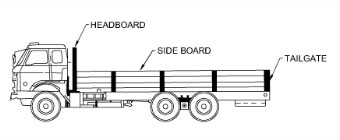

For loose bulk loads, a high sided vehicle will be necessary and although body height extensions are permitted but these should be purposely designed and constructed, and able to be attached to the existing body by appropriate fixings and not rely on the load for support. Loose bulk loads of any description must be levelled off and not be loaded above the headboard, sideboards or tailgate.

Incorrect

as load protrudes above sides, and plywood pieces have been used as height extensions.

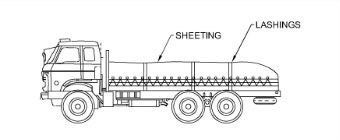

Correct method

using purpose designed vehicle for loose bulk loads, and completely covered with suitable sheeting to prevent any spillage.

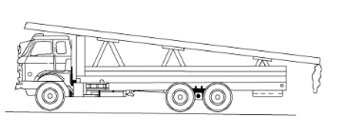

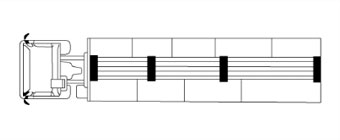

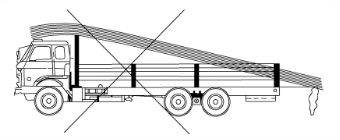

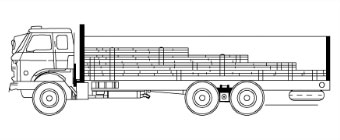

Long metal sections should be carried along the length of the vehicle and be suitably restrained to prevent them from moving. It is essential that these sections are loaded such that the complete load from a unit and no single item can move independently.

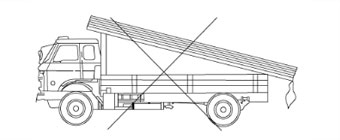

Unacceptable

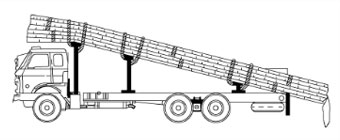

method loads too long for vehicle and inclined such that rear of load not adequately restrained and load distribution is also not satisfactory. Further, supporting the load only on the headboard and the extended tailgate is not acceptable and in fact the use of the tailgate to support any part of the load or as an anchorage point for the lashings is not acceptable.

Acceptable

method load is extended over the headboard and supported by suitable trestles firmly fixed to the vehicle. The load should also be securely lashed to the headboard and all the trestles but not to the tailgate.

Better methode

load is laid flat; however still has disadvantage that load is too long for vehicle.

Best method

loads laid flat and completely contained by vehicle. The load must be securely lashed to the headboard and the trestles to avoid any forward, rear or lateral movement.

Care should be taken while loading the vehicle to ensure that the load is not so arranged that the removal or pickup of any part of it in the course of a journey will adversely affect any axle weight, or the stability of the vehicle.

Load laid flat in purposefully designed vehicle.

Proper distribution of load with heavier items at the bottom and the lower packages should be strong enough to support the upper ones when the vehicle is braking, turning or accelerating.

Heavier items should be placed nearer the longitudinal centre line.

Acceptable

Long metal loads should be transported on suitable vehicles which enable the load to be laid flat without overhanging the rear of the vehicle if possible.

Not Acceptable

Use of the headboard and/or tailgate to support long metal loads is not acceptable. Securing the load to any part of the tailgate is also not acceptable.

For low-friction load items such as reinforcement steel bars or plastic pipes, the load should also be packed with end wraps or blocks to prevent individual the items from sliding or spearing out of the pack particularly when the vehicle is braking sharply.

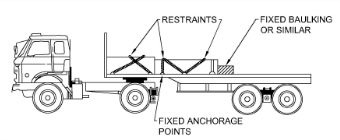

Use of load restraining devices will be necessary where general freight loads exceed the height of any headboard, sideboards or tailgate, load.

General freight carried on any platform type vehicles must have load restraining devices.

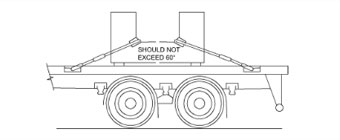

The angle between the lashing providing forward / backward restraint and the platform should not exceed 60˚

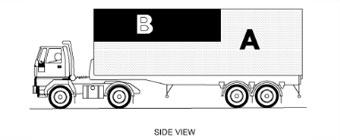

While transporting mixed load, lighter crushable items should be placed to the top and at the front, ‘B’, while heavy articles to the bottom and rear, ‘A’ as shown.

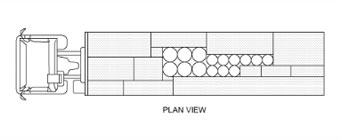

While transporting mixed load, small containers should be placed in centre while larger containers around the outside.

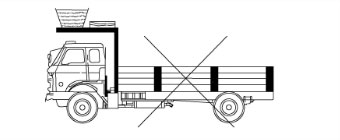

Not Acceptable

Loose baskets should not be carried on cab roof.

Not Acceptable

This loading method is not acceptable as roof supports are not sufficient on their own as restraint devices and lashings or similar must be provided to prevent any part of the load from falling off.

Mixed loads should always be covered by suitable means to prevent spillage and provide protection for load.

Not Acceptable

Vehicle has insufficient side restraint to prevent any loose palletized drink crates from falling off.

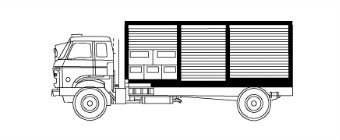

Acceptable

While Transporting Crates, sliding partition covers or lashings should ensure any loose crates are securely restrained within the vehicle.

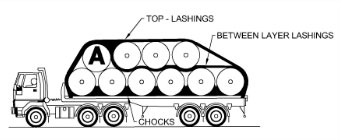

In case of rolls, bottom layer should be secured by chocks. Roll 'A' then loaded and "between layer lashings" then laid over 'A' as shown. Second layer should then be loaded, and both "top - lashings" and "between layer lashings" should be tensioned and secured.

Whole load should be covered with sheeting to provide additional lateral restraint and weather protection.

Drums containing liquid or liquefied material should be stood on end with suitable packing if necessary to prevent movement

Boxes should interlock and be covered Boxes and crates must be secured to floor of platform with at least one lashing for each row, and the whole load should be covered

Acceptable

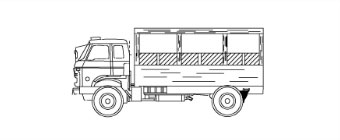

Sacks should be laid on their sides with alternate layers in opposite directions

Acceptable

The loaded sacks should where practicable be covered with a suitable sheeting and then cross lashed

Not Acceptable

Loose bricks must not be loaded above the side or tail boards

Acceptable

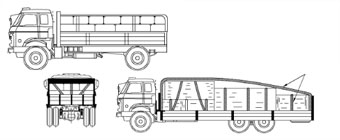

Bamboo poles should be loaded horizontally along the floor of the vehicle, which should be appropriately sized bundles, arranged with the longest and heaviest at the bottom of the load. If the load is not higher than the headboard, tailgate or sideboards, securing bundles together should provide sufficient restraint.

Acceptable

Where bamboo poles have to extend over the headboard, they should not be positioned any farther forward than the front of the cab, and the weight of the load should be supported by suitable trestles firmly fixed to the vehicle. The load should be securely lashed to the headboard and trestles and not to any part of the tailgate or its hinges.